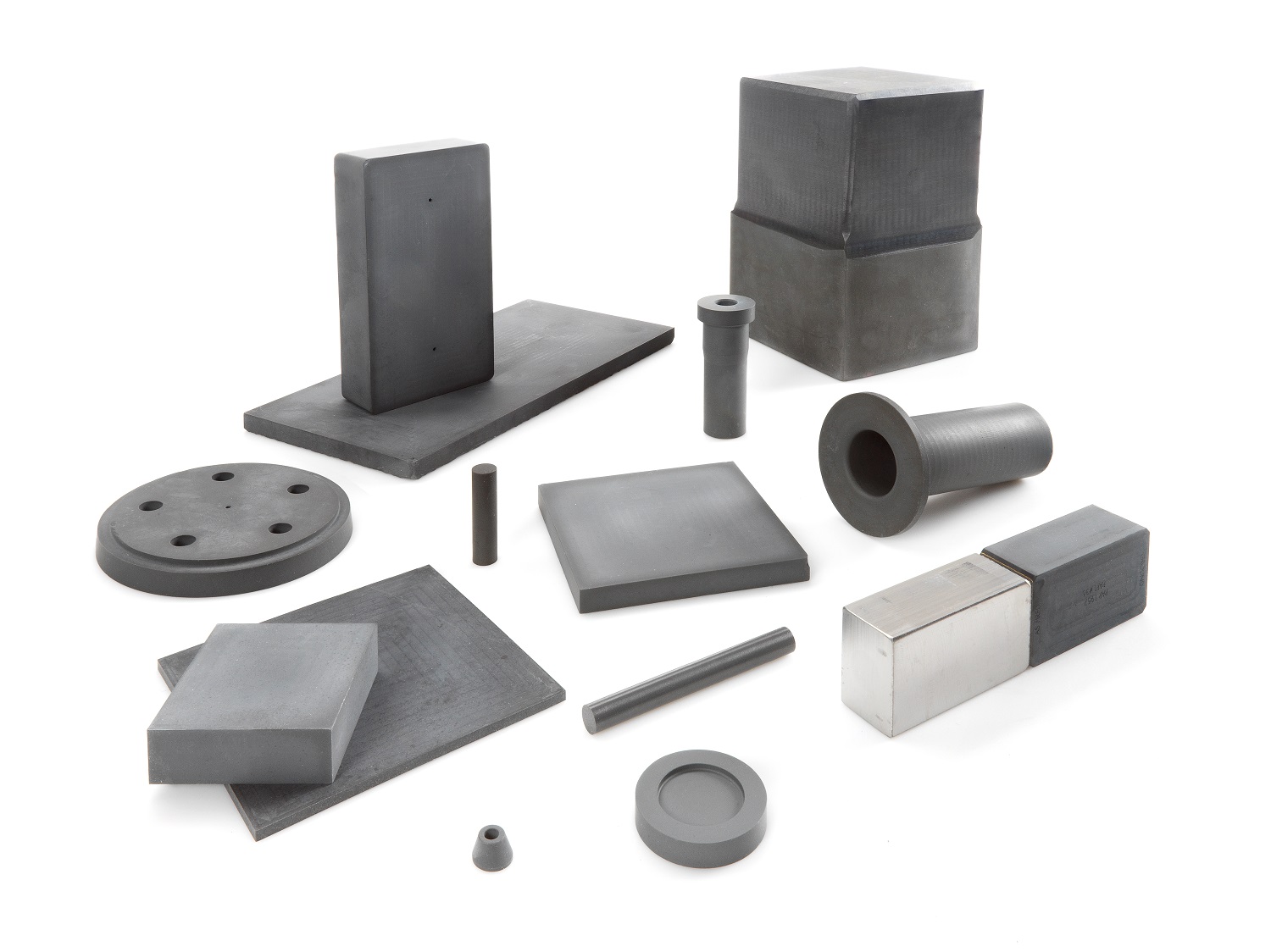

OEM COMPONENTS TO CONQUER THE TOUGHEST INDUSTRIAL CHALLENGES

SINTX is a leading industrial ceramics manufacturer with over 20 years of experience in ceramic manufacturing. We’ve formulated an advanced grade of silicon nitride (Si3N4), specifically optimized for high-performance industrial applications. STX-100 offers the best combination of mechanical, thermal, and electrical properties of any industrial ceramic. This advanced ceramic material is characterized by its density, strength, and design flexibility. Consult with our team of experts to discuss an industrial ceramic solution for your project.